Table of Contents

.

This manual is a work in progress. If you are able to help with writing, editing, or graphic preparation please contact any member of the writing team or join and send an email to emc-users@lists.sourceforge.net.

Copyright (c) 2000-9 LinuxCNC.org

Permission is granted to copy, distribute and/or modify this document under the terms of the GNU Free Documentation License, Version 1.1 or any later version published by the Free Software Foundation; with no Invariant Sections, no Front-Cover Texts, and one Back-Cover Text: This EMC Handbook is the product of several authors writing for linuxCNC.org. As you find it to be of value in your work, we invite you to contribute to its revision and growth.A copy of the license is included in the section entitled GNU Free Documentation License. If you do not find the license you may order a copy from Free Software Foundation, Inc. 59 Temple Place, Suite 330 Boston, MA 02111-1307

BASE_PERIOD is the "heartbeat" of your EMC computer. Every period, the software step generator decides if it is time for another step pulse. A shorter period will allow you to generate more pulses per second, within limits. But if you go too short, your computer will spend so much time generating step pulses that everything else will slow to a crawl, or maybe even lock up. Latency and stepper drive requirements affect the shortest period you can use.

Worst case latencies might only happen a few times a minute, and the odds of bad latency happening just as the motor is changing direction are low. So you can get very rare errors that ruin a part every once in a while and are impossible to troubleshoot.

The simplest way to avoid this problem is to choose a BASE_PERIOD that is the sum of the longest timing requirement of your drive, and the worst case latency of your computer. This is not always the best choice for example if you are running a drive with a 20uS hold time requirement, and your latency test said you have a maximum latency of 11uS, then if you set the BASE_PERIOD to 20+11 = 31uS and a not-so-nice 16,129 steps per second.

The problem is with the 20uS hold time requirement. That plus the 11uS latency is what forces us to use a slow 31uS period. But the EMC2 software step generator has some parameters that let you increase the various time from one period to several. For example, if steplen is changed from 1 to 2, then it there will be two periods between the beginning and end of the step pulse. Likewise, if dirhold is changed from 1 to 3, there will be at least three periods between the step pulse and a change of the direction pin.

If we can use dirhold to meet the 20uS hold time requirement, then the next longest time is the 4.5uS high time. Add the 11uS latency to the 4.5uS high time, and you get a minimum period of 15.5uS. When you try 15.5uS, you find that the computer is sluggish, so you settle on 16uS. If we leave dirhold at 1 (the default), then the minimum time between step and direction is the 16uS period minus the 11uS latency = 5uS, which is not enough. We need another 15uS. Since the period is 16uS, we need one more period. So we change dirhold from 1 to 2. Now the minimum time from the end of the step pulse to the changing direction pin is 5+16=21uS, and we don’t have to worry about the drive stepping the wrong direction because of latency.

For more information on stepgen see Section ( [sec:Stepgen]).

Servo systems must be "tuned" as they don’t quite work out of the box like a stepper system might. This is because servos don’t "step" in fixed increments like steppers do. PID is the "Black Magic" that makes your servos move where you want them to move and when you want them to move.

PID stand for Proportional, Integral, and Derivative. The Proportional value determines the reaction to the current error, the Integral value determines the reaction based on the sum of recent errors, and the Derivative value determines the reaction based on the rate at which the error has been changing. They are three common mathematical techniques that are applied to the task of getting a working process to follow a set point. In the case of EMC the process we want to control is actual axis position and the set point is the commanded axis position.

By "tuning" the three constants in the PID controller algorithm, the controller can provide control action designed for specific process requirements. The response of the controller can be described in terms of the responsiveness of the controller to an error, the degree to which the controller overshoots the set point and the degree of system oscillation.

The proportional term (sometimes called gain) makes a change to the output that is proportional to the current error value. A high proportional gain results in a large change in the output for a given change in the error. If the proportional gain is too high, the system can become unstable. In contrast, a small gain results in a small output response to a large input error. If the proportional gain is too low, the control action may be too small when responding to system disturbances.

In the absence of disturbances, pure proportional control will not settle at its target value, but will retain a steady state error that is a function of the proportional gain and the process gain. Despite the steady-state offset, both tuning theory and industrial practice indicate that it is the proportional term that should contribute the bulk of the output change.

The contribution from the integral term (sometimes called reset) is proportional to both the magnitude of the error and the duration of the error. Summing the instantaneous error over time (integrating the error) gives the accumulated offset that should have been corrected previously. The accumulated error is then multiplied by the integral gain and added to the controller output.

The integral term (when added to the proportional term) accelerates the movement of the process towards set point and eliminates the residual steady-state error that occurs with a proportional only controller. However, since the integral term is responding to accumulated errors from the past, it can cause the present value to overshoot the set point value (cross over the set point and then create a deviation in the other direction).

The rate of change of the process error is calculated by determining the slope of the error over time (i.e. its first derivative with respect to time) and multiplying this rate of change by the derivative gain.

The derivative term slows the rate of change of the controller output and this effect is most noticeable close to the controller set point. Hence, derivative control is used to reduce the magnitude of the overshoot produced by the integral component and improve the combined controller-process stability.

If the PID controller parameters (the gains of the proportional, integral and derivative terms) are chosen incorrectly, the controlled process input can be unstable, i.e. its output diverges, with or without oscillation, and is limited only by saturation or mechanical breakage. Tuning a control loop is the adjustment of its control parameters (gain/proportional band, integral gain/reset, derivative gain/rate) to the optimum values for the desired control response.

A simple tuning method is to first set the I and D values to zero. Increase the P until the output of the loop oscillates, then the P should be set to be approximately half of that value for a "quarter amplitude decay" type response. Then increase I until any offset is correct in sufficient time for the process. However, too much I will cause instability. Finally, increase D, if required, until the loop is acceptably quick to reach its reference after a load disturbance. However, too much D will cause excessive response and overshoot. A fast PID loop tuning usually overshoots slightly to reach the set point more quickly; however, some systems cannot accept overshoot, in which case an "over-damped" closed-loop system is required, which will require a P setting significantly less than half that of the P setting causing oscillation.

The Real Time Application Interface (RTAI) is used to provide the best Real Time (RT) performance. The RTAI patched kernel lets you write applications with strict timing constraints. RTAI gives you the ability to have things like software step generation which require precise timing.

The Advanced Configuration and Power Interface (ACPI) has a lot of different functions, most of which interfere with RT performance (for example: power management, CPU power down, CPU frequency scaling, etc). The EMC2 kernel (and probably all RTAI-patched kernels) has ACPI disabled. ACPI also takes care of powering down the system after a shutdown has been started, and that’s why you need to push the power button to completely turn off your computer.

The EMC is configured with human readable text files. All of these files can be read and edited in any of the common text file editors available with most any Linux distribution.[1] You’ll need to be a bit careful when you edit these files. Some mistakes will cause the start up to fail. These files are read whenever the software starts up. Some of them are read repeatedly while the CNC is running.

Configuration files include

- INI

- The ini file overrides defaults that are compiled into the EMC code. It also provides sections that are read directly by the Hardware Abstraction Layer.

- HAL

- The HAL files start up process modules and provide linkages between EMC signals and specific hardware pins.

- VAR

- The var file is a way for the interpreter to save some values from one run to the next. These values are saved from one run to another but not always saved immediately. See the Parameters section of the G Code Manual for information on what each parameter is.

- TBL

- The tbl file saves tool information. See the User Manual Tool File section for more info.

- NML

- The nml file configures the communication channels used by the EMC. It is normally setup to run all of the communication within a single computer but can be modified to communicate between several computers.

emcrc::

(((.emcrc))) This file saves user specific information and is created to save the name of the directory when the user first selects an EMC configuration.footnote:[Usually this file is in the users home directory (e.g. /home/user/ ) ]

Items marked (hal) are used only by the sample HAL files and are suggested as a good convention. Other items are used by EMC directly, and must always have the section and item names given.

[1] Don’t confuse a text editor with a word processor. A text editor like gedit or kwrite produce files that are plain text. They also produce lines of text that are separated from each other. A word processor like Open Office produce files with paragraphs and word wrapping and lots of embedded codes that control font size and such. A text editor does none of this.

A typical INI file follows a rather simple layout that includes;

- comments.

- sections,

- variables.

Each of these elements is separated on single lines. Each end of line or newline character creates a new element.

A comment line is started with a ; or a # mark. When the ini reader sees either of these marks at the start a line, the rest of the line is ignored by the software. Comments can be used to describe what some INI element will do.

; This is my little mill configuration file. ; I set it up on January 12, 2006

Comments can also be used to select between several values of a single variable.

DISPLAY = axis # DISPLAY = touchy

In this list, the DISPLAY variable will be set to axis because the other one is commented out. If someone carelessly edits a list like this and leaves two of the lines uncommented, the first one encountered will be used.

Note that inside a variable, the "#" and ";" characters do not denote comments:

INCORRECT = value # and a comment # Correct Comment CORRECT = value

Related parts of an ini file are separated into sections. A section line looks like [THIS_SECTION]. The name of the section is enclosed in brackets. The order of sections is unimportant. The following sections are used by EMC:

- [EMC] general information ( [sub:[EMC]-section])

- [DISPLAY] settings related to the graphical user interface ( [sub:[DISPLAY]-section])

- [FILTER] settings input filter programs ([sub:[FILTER]-Section])

- [RS274NGC] settings used by the g-code interpreter ( [sub:[RS274NGC]-section])

- [EMCMOT] settings used by the real time motion controller ( [sub:[EMCMOT]-section])

- [HAL] specifies .hal files ( [sub:[HAL]-section])

- [TASK] settings used by the task controller ( [sub:[TASK]-section])

- [TRAJ] additional settings used by the real time motion controller ( [sub:[TRAJ]-section])

- [AXIS_0] … [AXIS_n] individual axis variables ( [sub:[AXIS]-section])

- [EMCIO] settings used by the I/O Controller ( [sub:[EMCIO]-Section])

- [HALUI] MDI commands used by HALUI. See the HALUI chapter for more information ( [sub:MDI])

A variable line is made up of a variable name, an equals sign(=), and a value. Everything from the first non-white space character after the = up to the end of the line is passed as the value, so you can embed spaces in string symbols if you want to or need to. A variable name is often called a keyword.

The following sections detail each section of the configuration file, using sample values for the configuration lines.

Some of the variables are used by EMC, and must always use the section names and variable names shown. Other variables are used only by HAL, and the section names and variable names shown are those used in the sample configuration files.

- VERSION

- =* *$Revision:* *1.3* *$ The version number for the INI file. The value shown here looks odd because it is automatically updated when using the Revision Control System. It’s a good idea to change this number each time you revise your file. If you want to edit this manually just change the number and leave the other tags alone.

- MACHINE

- =* *My* *Controller This is the name of the controller, which is printed out at the top of most graphical interfaces. You can put whatever you want here as long as you make it a single line long.

- DEBUG = 0

- Debug level 0 means no messages will be printed when EMC is run from a terminal. Debug flags are usually only useful to developers. See src/emc/nml_int/emcglb.h for other settings.

Different user interface programs use different options, and not every option is supported by every user interface. The main two interfaces for EMC are AXIS and Touchy. Axis is an interface for use with normal computer and monitor, Touchy is for use with touch screens. Descriptions of the interfaces are in the Interfaces section of the User Manual.

DISPLAY = axis The name of the user interface to use. Valid options may include:

- axis

- touchy

- keystick

- mini

- tkemc

- POSITION_OFFSET = RELATIVE

- The coordinate system (RELATIVE or MACHINE) to show when the user interface starts. The RELATIVE coordinate system reflects the G92 and G5x coordinate offsets currently in effect.

- POSITION_FEEDBACK = ACTUAL

- The coordinate value (COMMANDED or ACTUAL) to show when the user interface starts. The COMMANDED position is the ideal position requested by EMC. The ACTUAL position is the feedback position of the motors.

- MAX_FEED_OVERRIDE = 1.2

- The maximum feed override the user may select. 1.2 means 120% of the programmed feed rate

- MIN_SPINDLE_OVERRIDE = 0.5

- The minimum spindle override the user may select. 0.5 means 50% of the programmed spindle speed. (This is useful as it’s dangerous to run a program with a too low spindle speed).

- MAX_SPINDLE_OVERRIDE = 1.0

- The maximum spindle override the user may select. 1.0 means 100% of the programmed spindle speed

- PROGRAM_PREFIX = ~/emc2/nc_files

- The default location for g-code files and the location for user-defined M-codes

- INTRO_GRAPHIC = emc2.gif

- The image shown on the splash screen

- INTRO_TIME = 5

- The maximum time to show the splash screen

- CYCLE_TIME = 0.0500

- Cycle time in seconds that display will sleep between polls.

The following [DISPLAY] items are used only if you select AXIS as your user interface program.

- DEFAULT_LINEAR_VELOCITY = .25

- The default velocity for linear jogs, in machine units per second.

- MIN_VELOCITY = .01

- The approximate lowest value the jog slider.

- MAX_LINEAR_VELOCITY = 1.0

- The maximum velocity for linear jogs, in machine units per second.

- MIN_LINEAR_VELOCITY = .01

- The approximate lowest value the jog slider.

- DEFAULT_ANGULAR_VELOCITY = .25

- The default velocity for angular jogs, in machine units per second.

- MIN_ANGULAR_VELOCITY = .01

- The approximate lowest value the jog slider.

- MAX_ANGULAR_VELOCITY = 1.0

- The maximum velocity for angular jogs, in machine units per second.

- INCREMENTS = 1 mm, .5 in, …

- Defines the increments available for incremental jogs. The INCREMENTS can be used to override the default. The values can be decimal numbers (e.g., 0.1000) or fractional numbers (e.g., 1/16), optionally followed by a unit (cm, mm, um, inch, in or mil). If a unit is not specified the machine unit is assumed. Metric and imperial distances may be mixed: INCREMENTS = 1 inch, 1 mil, 1 cm, 1 mm, 1 um is a valid entry.

- OPEN_FILE = /full/path/to/file.ngc

- The file to show in the preview plot when AXIS starts. Use a blank string "" and no file will be loaded at start up.

- EDITOR = gedit

- The editor to use when selecting File > Edit or File Edit Tool Table from the AXIS menu. This must be configured for these menu items to work. Another valid entry is gnome-terminal -e vim.

- PYVCP = /filename.xml

- The pyVCP panel description file. See the pyVCP section for more information.

- LATHE = 1

- This displays in lathe mode with a top view and with Radius and Diameter on the DRO.

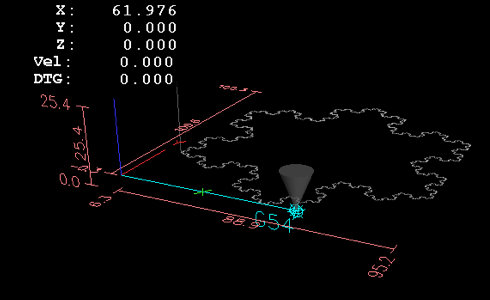

- GEOMETRY = XYZABCUVW

-

Controls the preview and backplot of rotary motion. This item consists

of a sequence of axis letters, optionally preceded by a "-" sign. Only

axes defined in

[TRAJ]AXESshould be used. This sequence specifies the order in which the effect of each axis is applied, with a "-" inverting the sense of the rotation. The proper GEOMETRY string depends on the machine configuration and the kinematics used to control it. The example string GEOMETRY=XYZBCUVW is for a 5-axis machine where kinematics causes UVW to move in the coordinate system of the tool and XYZ to move in the coordinate system of the material. The order of the letters is important, because it expresses the order in which the different transformations are applied. For example rotating around C then B is different than rotating around B then C. Geometry has no effect without a rotary axis. - ARCDIVISION = 64

- Set the quality of preview of arcs. Arcs are previewed by dividing them into a number of straight lines; a semicircle is divided into ARCDIVISION parts. Larger values give a more accurate preview, but take longer to load and result in a more sluggish display. Smaller values give a less accurate preview, but take less time to load and may result in a faster display. The default value of 64 means a circle of up to 3 inches will be displayed to within 1 mil (.03%).[2]

- MDI_HISTORY_FILE =

- The name of a local MDI history file. If this is not specified Axis will save the MDI history in /home/~/.axis_mdi_history in the home directory. This is useful if you have multiple configurations on one computer.

The following [DISPLAY] items are not used if you select AXIS as your user interface program.

- HELP_FILE = tkemc.txt

- Path to help file (not used in AXIS).

AXIS has the ability to send loaded files through a filter program. This filter can do any desired task: Something as simple as making sure the file ends with M2, or something as complicated as detecting whether the input is a depth image, and generating g-code to mill the shape it defines. The [FILTER] section of the ini file controls how filters work. First, for each type of file, write a PROGRAM_EXTENSION line. Then, specify the program to execute for each type of file. This program is given the name of the input file as its first argument, and must write rs274ngc code to standard output. This output is what will be displayed in the text area, previewed in the display area, and executed by EMC when Run.

- PROGRAM_EXTENSION = .extension Description

If your post processor outputs files in all caps you might want to add the following line:

PROGRAM_EXTENSION = .NGC XYZ Post Processor

The following lines add support for the image-to-gcode converter included with EMC2:

PROGRAM_EXTENSION = .png,.gif Greyscale Depth Image

It is also possible to specify an interpreter:

PROGRAM_EXTENSION = .py Python Script

In this way, any Python script can be opened, and its output is treated as g-code. One such example script is available at nc_files/holecircle.py. This script creates g-code for drilling a series of holes along the circumference of a circle. Many more g-code generators are on the EMC Wiki site http://wiki.linuxcnc.org/cgi-bin/emcinfo.pl.

If the environment variable AXIS_PROGRESS_BAR is set, then lines written to stderr of the form

FILTER_PROGRESS=%d

Sets the AXIS progress bar to the given percentage. This feature should be used by any filter that runs for a long time.

Example:

PARAMETER_FILE = myfile.var

Example:

- SUBROUTINE_PATH

- Specifies a colon (:) separated list of up to 10 directories to be searched when single-file subroutines are specified in gcode. These directories are searched after searching [DISPLAY]PROGRAM_PREFIX (if it is specified) and before searching [WIZARD]WIZARD_ROOT (if specified). The first matching subroutine file found in the search is used. Directories are specified relative to the current directory for the inifile or as absolute paths. The list must contain no intervening whitespace.

Example:

SUBROUTINE_PATH = ncsubroutines:/tmp/testsubs:lathesubs:millsubs

- USER_M_PATH

- specifies a list of colon (:) separated directories (no intervening whitespace) for user defined functions. The maximum number of directories is defined at compile time by: USER_DEFINED_FUNCTION_MAX_DIRS=5. Directories are specified relative to the current directory for the inifile or as absolute paths. The list must contain no intervening whitespace.

Example:

USER_M_PATH = myfuncs:/tmp/mcodes:experimentalmcodes

A search is made for each possible user defined function, typically (M100-M199). The search order is:

- [DISPLAY]PROGRAM_PREFIX (if specified)

- If [DISPLAY]PROGRAM_PREFIX is not specified, search the default location: nc_files

- Then search each directory in the list [RS274NGC]USER_M_PATH

The first executable M1xx found in the search is used for each M1xx.

You may find other entries in this section and they should not be changed.

- BASE_PERIOD

- = 50000 (hal) "Base" task period, in nanoseconds - this is the fastest thread in the machine. On servo-based systems, there is generally no reason for BASE_PERIOD to be smaller than SERVO_PERIOD. On machines with software step generation, the BASE_PERIOD determines the maximum number of steps per second. In the absence of long step length and step space requirements, the absolute maximum step rate is one step per BASE_PERIOD. Thus, the BASE_PERIOD shown above gives an absolute maximum step rate of 20000 steps per second. 50000ns is a fairly conservative value. The smallest usable value is related to the Latency Test result, the necessary step length, and the processor speed. Choosing a BASE_PERIOD that is too low can lead to the "Unexpected real time delay" message, lockups, or spontaneous reboots.

- SERVO_PERIOD

- = 1000000 (hal) "Servo" task period is also in nanoseconds. This value will be rounded to an integer multiple of BASE_PERIOD. This value is used even on systems based on stepper motors. This is the rate at which new motor positions are computed, following error is checked, PID output values are updated, and so on. Most systems will not need to change this value. It is the update rate of the low level motion planner.

- TRAJ_PERIOD

- = 1000000 *(hal) Trajectory Planner task period in nanoseconds This value will be rounded to an integer multiple of *SERVO_PERIOD. Except for machines with unusual kinematics (e.g., hexapods) there is no reason to make this value larger than SERVO_PERIOD.

- TASK = milltask

- Specifies the name of the "task" executable. "task" does various things, such as communicate with the UIs over NML, communicate with the realtime motion planner over non-HAL shared memory, and interpret gcode. Currently there is only one task executable that makes sense for 99.9% of users, milltask In the dim mists of time (before HAL), it was frequently the case that an integrator would have to build a modified version of things like task, io, and motion for a specific machine.

- CYCLE_TIME

- =* *0.0 01 The period, in seconds, at which EMCTASK will run. This parameter affects the polling interval when waiting for motion to complete, when executing a pause instruction, and when accepting a command from a user interface. There is usually no need to change this number.

- HALFILE = example.hal

-

Execute the file example.hal at start up. If HALFILE is specified

multiple times, the files are executed in the order they

appear in the ini file. Almost all configurations will have at least

one HALFILE , and stepper systems typically have two such files, one

which

specifies the generic stepper configuration (

core_stepper.hal) and one which specifies the machine pin out (xxx_pinout.hal) - HALCMD = command

- Execute command as a single hal command. If HALCMD is specified multiple times, the commands are executed in the order they appear in the ini file. HALCMD lines are executed after all HALFILE lines.

- SHUTDOWN = shutdown.hal

- Execute the file shutdown.hal when EMC is exiting. Depending on the hardware drivers used, this may make it possible to set outputs to defined values when EMC is exited normally. However, because there is no guarantee this file will be executed (for instance, in the case of a computer crash) it is not a replacement for a proper physical e-stop chain or other protections against software failure.

- POSTGUI_HALFILE = example2.hal

- (Only with the AXIS GUI) Execute example2.hal after the GUI has created its HAL pins. See section [sec:pyvcp-with-axis] for more information.

The [TRAJ] section contains general parameters for the trajectory planning module in EMCMOT.

- COORDINATES

- =* *X* Y* Z The names of the axes being controlled. X, Y, Z, A, B, C, U, V, and W are all valid. Only axis named in COORDINATES are accepted in g-code. This has no effect on the mapping from G-code axis names (X- Y- Z-) to joint numbers—for "trivial kinematics", X is always joint 0, A is always joint 4, and U is always joint 7, and so on. It is permitted to write an axis name twice (e.g., X Y Y Z for a gantry machine) but this has no effect.

- AXES = 3

- One more than the number of the highest joint number in the system. For an XYZ machine, the joints are numbered 0, 1 and 2; in this case AXES should be 3. For an XYUV machine using "trivial kinematics", the V joint is numbered 7 and therefore AXES should be 8. For a machine with nontrivial kinematics (e.g., scarakins) this will generally be the number of controlled joints.

- HOME

- =* *0* *0* *0 Coordinates of the homed position of each axis. Again for a fourth axis you will need 0 0 0 0. This value is only used for machines with nontrivial kinematics. On machines with trivial kinematics this value is ignored.

- LINEAR_UNITS = <units>

- Specifies the machine units for linear axes. Possible choices are (in, inch, imperial, metric, mm). This does not affect the linear units in NC code (the G20 and G21 words do this).

- ANGULAR_UNITS = <units>

- Specifies the machine units for rotational axes. Possible choices are deg, degree (360 per circle), rad, radian (2pi per circle), grad, or gon (400 per circle). This does not affect the angular units of NC code. In RS274NGC, A-, B- and C- words are always expressed in degrees.

- DEFAULT_VELOCITY

- = 0.0167 The initial rate for jogs of linear axes, in machine units per second. The value shown equals one unit per minute.

- DEFAULT_ACCELERATION

- = 2.0 In machines with nontrivial kinematics, the acceleration used for "teleop" (Cartesian space) jogs, in machine units per second per second.

- MAX_VELOCITY = 5.0

- The maximum velocity for any axis or coordinated move, in machine units per second. The value shown equals 300 units per minute.

- MAX_ACCELERATION = 20.0

- The maximum acceleration for any axis or coordinated axis move, in machine units per second per second.

- POSITION_FILE = position.txt

- If set to a non-empty value, the joint positions are stored between runs in this file. This allows the machine to start with the same coordinates it had on shutdown. This assumes there was no movement of the machine while powered off. If unset, joint positions are not stored and will begin at 0 each time EMC is started. This can help on smaller machines without home switches.

- NO_FORCE_HOMING = 1

The default behavior is for EMC to force the user to home the machine before any MDI command or a program is run. Normally jogging only is allowed before homing. Setting NO_FORCE_HOMING = 1 allows the user to make MDI moves and run programs without homing the machine first. Interfaces without homing ability will need to have this option set to

- * Warning* : Using this will allow the machine to run past soft limits while in operation and is not generally desirable to allow this.

The [AXIS_0], [AXIS_1], etc. sections contains general parameters for the individual components in the axis control module. The axis section names begin numbering at 0, and run through the number of axes specified in the [TRAJ] AXES entry minus 1.

- AXIS_0 = X

- AXIS_1 = Y

- AXIS_2 = Z

- AXIS_3 = A

- AXIS_4 = B

- AXIS_5 = C

- AXIS_6 = U

- AXIS_7 = V

AXIS_8 = W

- TYPE = LINEAR

- The type of axes, either LINEAR or ANGULAR.

- WRAPPED_ROTARY = 1

- When this is set to 1 for an ANGULAR axis the axis will move 0-359.999 degrees. Plus Numbers will move the axis in a positive direction and minus numbers will move the axis in the opposite direction.

- UNITS

- = inch If specified, this setting overrides the related [TRAJ] UNITS setting. (e.g., [TRAJ]LINEAR_UNITS if the TYPE of this axis is LINEAR, [TRAJ]ANGULAR_UNITS if the TYPE of this axis is ANGULAR)

- MAX_VELOCITY = 1.2

- Maximum velocity for this axis in machine units per second.

- MAX_ACCELERATION

- =* *20.0 Maximum acceleration for this axis in machine units per second squared.

- BACKLASH

- =* *0.000 Backlash in machine units. Backlash compensation value can be used to make up for small deficiencies in the hardware used to drive an axis. If backlash is added to an axis and you are using steppers the STEPGEN_MAXACCEL must be increased to 1.5 to 2 times the MAX_ACCELERATION for the axis.

- COMP_FILE = file.extension

- A file holding compensation structure for the axis. The file could be named xscrew.comp for example for the X axis. File names are case sensitive and can contain letters and or numbers. The values are triplets per line separated by a space. The first value is nominal (where it should be). The second and third values depend on the setting of COMP_FILE_TYPE. Currently the limit inside EMC2 is for 256 triplets per axis. If COMP_FILE is specified, BACKLASH is ignored. Compensation file values are in machine units.

- COMP_FILE_TYPE=0 the second and third values specify the forward position (where the axis is while traveling forward) and reverse position (where the axis is while traveling reverse) positions which correspond to the nominal position.

COMP_FILE_TYPE=1 the second and third values specify the forward trim (how far from nominal while traveling forward) and the reverse trim (how far from nominal while traveling in reverse).

- COMP_FILE_TYPE = 0

- For COMP_FILE_TYPE of zero, the values in the compensation file are nominal, forward & reverse. For COMP_FILE_TYPE of non-zero the values in the compensation file are nominal, forward_trim and reverse_trim.

- MIN_LIMIT

- = -1000 The minimum limit (soft limit) for axis motion, in machine units. When this limit is exceeded, the controller aborts axis motion.

- MAX_LIMIT

- = 1000 The maximum limit (soft limit) for axis motion, in machine units. When this limit is exceeded, the controller aborts axis motion.

- MIN_FERROR

- =* *0.010 This is the value in machine units by which the axis is permitted to deviate from commanded position at very low speeds. If MIN_FERROR is smaller than FERROR, the two produce a ramp of error trip points. You could think of this as a graph where one dimension is speed and the other is permitted following error. As speed increases the amount of following error also increases toward the FERROR value.

- FERROR

- = 1.0 FERROR is the maximum allowable following error, in machine units. If the difference between commanded and sensed position exceeds this amount, the controller disables servo calculations, sets all the outputs to 0.0, and disables the amplifiers. If MIN_FERROR is present in the .ini file, velocity-proportional following errors are used. Here, the maximum allowable following error is proportional to the speed, with FERROR applying to the rapid rate set by [TRAJ]MAX_VELOCITY, and proportionally smaller following errors for slower speeds. The maximum allowable following error will always be greater than MIN_FERROR. This prevents small following errors for stationary axes from inadvertently aborting motion. Small following errors will always be present due to vibration, etc. The following polarity values determine how inputs are interpreted and how outputs are applied. They can usually be set via trial-and-error since there are only two possibilities. The EMC2 Servo Axis Calibration utility program (in the AXIS interface menu Machine/Calibration and in TkEMC it is under Setting/Calibration) can be used to set these and more interactively and verify their results so that the proper values can be put in the INI file with a minimum of trouble.

These parameters are Homing related, for a better explanation read the Homing Section ( [sec:Homing]).

- HOME = 0.0

- The position that the joint will go to upon completion of the homing sequence.

- HOME_OFFSET

- = 0.0 The axis position of the home switch or index pulse, in machine units.

- HOME_SEARCH_VEL

- =* *0.0 Initial homing velocity in machine units per second. Sign denotes direction of travel. A value of zero means assume that the current location is the home position for the machine. If your machine has no home switches you will want to leave this value alone.

- HOME_LATCH_VEL

- =* *0.0 Homing velocity in machine units per second to the home switch latch position. Sign denotes direction of travel.

- HOME_FINAL_VEL = 0.0

- Velocity in machine units per second from home latch position to home position. If left at 0 or not included in the axis rapid velocity is used. Must be a positive number.

- HOME_USE_INDEX

- =* *NO If the encoder used for this axis has an index pulse, and the motion card has provision for this signal you may set it to yes. When it is yes, it will affect the kind of home pattern used. Currently, you can’t home to index with steppers unless your using stepgen in velocity mode and pid.

- HOME_IGNORE_LIMITS

- = NO Some machines use a single switch as a home switch and limit switch. This variable should be set to yes if the machine configured this way.

- HOME_IS_SHARED = <n>

- If the home input is shared by more than one axis set <n> to 1 to prevent homing from starting if the one of the shared switches is already closed. Set <n> to 0 to permit homing if a switch is closed.

- HOME_SEQUENCE = <n>

- Used to define the "Home All" sequence. <n> starts at 0 and no numbers may be skipped. If left out or set to -1 the joint will not be homed by the "Home All" function. More than one axis can be homed at the same time.

- VOLATILE_HOME = 0

- When enabled (set to 1) this joint will be unhomed if the Machine Power is off or if E-Stop is on. This is useful if your machine has home switches and does not have position feedback such as a step and direction driven machine.

The following items are for servo-based systems and servo-like systems. This description assumes that the units of output from the PID component are volts.

- DEADBAND = 0.000015

- (HAL) How close is close enough the consider the motor in position.

- BIAS = 0.000

- (HAL) This is used by hm2-servo and some others. Bias is a constant amount that is added to the output. In most cases it should be left at zero. However, it can sometimes be useful to compensate for offsets in servo amplifiers, or to balance the weight of an object that moves vertically. bias is turned off when the PID loop is disabled, just like all other components of the output.

- P

- =* *50 (hal) The proportional gain for the axis servo. This value multiplies the error between commanded and actual position in machine units, resulting in a contribution to the computed voltage for the motor amplifier. The units on the P gain are volts per machine unit, e.g., .

- I

- = 0 (hal) The integral gain for the axis servo. The value multiplies the cumulative error between commanded and actual position in machine units, resulting in a contribution to the computed voltage for the motor amplifier. The units on the I gain are volts per machine unit second, e.g., .

- D

- = 0 (hal) The derivative gain for the axis servo. The value multiplies the difference between the current and previous errors, resulting in a contribution to the computed voltage for the motor amplifier. The units on the D gain are volts per machine unit per second, e.g., .

- FF0

- = 0 (hal) The 0th order feed forward gain. This number is multiplied by the commanded position, resulting in a contribution to the computed voltage for the motor amplifier. The units on the FF0 gain are volts per machine unit, e.g., .

- FF1

- = 0 (hal) The 1st order feed forward gain. This number is multiplied by the change in commanded position per second, resulting in a contribution to the computed voltage for the motor amplifier. The units on the FF1 gain are volts per machine unit per second, e.g., .

- FF2

- = 0 (hal) The 2nd order feed forward gain. This number is multiplied by the change in commanded position per second per second, resulting in a contribution to the computed voltage for the motor amplifier. The units on the FF2 gain are volts per machine unit per second per second, e.g., .

- OUTPUT_SCALE

- =* *1.000

- OUTPUT_OFFSET =

0.000 (hal) These two values are the scale and offset factors for the axis output to the motor amplifiers. The second value (offset) is subtracted from the computed output (in volts), and divided by the first value (scale factor), before being written to the D/A converters. The units on the scale value are in true volts per DAC output volts. The units on the offset value are in volts. These can be used to linearize a DAC. Specifically, when writing outputs, the EMC first converts the desired output in quasi-SI units to raw actuator values, e.g., volts for an amplifier DAC. This scaling looks like: The value for scale can be obtained analytically by doing a unit analysis, i.e., units are [output SI units]/[actuator units]. For example, on a machine with a velocity mode amplifier such that 1 volt results in 250 mm/sec velocity, Note that the units of the offset are in machine units, e.g., mm/sec, and they are pre-subtracted from the sensor readings. The value for this offset is obtained by finding the value of your output which yields 0.0 for the actuator output. If the DAC is linearized, this offset is normally 0.0. The scale and offset can be used to linearize the DAC as well, resulting in values that reflect the combined effects of amplifier gain, DAC non-linearity, DAC units, etc. To do this, follow this procedure:

- Build a calibration table for the output, driving the DAC with a desired voltage and measuring the result. See table [cap:Output-Voltage-Measurements] for an example of voltage measurements.

- Do a least-squares linear fit to get coefficients a, b such that

- Note that we want raw output such that our measured result is identical to the commanded output. This means

- As a result, the a and b coefficients from the linear fit can be used as the scale and offset for the controller directly.

- MAX_OUTPUT

- *= 10 *(hal) The maximum value for the output of the PID compensation that is written to the motor amplifier, in volts. The computed output value is clamped to this limit. The limit is applied before scaling to raw output units. The value is applied symmetrically to both the plus and the minus side.

| Raw | Measured |

|---|---|

-10 | -9.93 |

-9 | -8.83 |

0 | -0.03 |

1 | 0.96 |

9 | 9.87 |

10 | 10.87 |

- INPUT_SCALE

- = 20000 (hal) Specifies the number of pulses that corresponds to a move of one machine unit as set in the [TRAJ] section. For a linear axis one machine unit will be equal to the setting of LINEAR_UNITS. For an angular axis one unit is equal to the setting in ANGULAR_UNITS. A second number, if specified, is ignored. For example, on a 2000 counts per rev encoder, and 10 revs/inch gearing, and desired units of inch, we have

The following items are Stepper related items.

- SCALE

- = 4000 (hal) Specifies the number of pulses that corresponds to a move of one machine unit as set in the [TRAJ] section. For stepper systems, this is the number of step pulses issued per machine unit. For a linear axis one machine unit will be equal to the setting of LINEAR_UNITS. For an angular axis one unit is equal to the setting in ANGULAR_UNITS. For servo systems, this is the number of feedback pulses per machine unit. A second number, if specified, is ignored. For example, on a 1.8 degree stepper motor with half-stepping, and 10 revs/inch gearing, and desired machine units of inch, we have Older stepper configuration .ini and .hal used INPUT_SCALE for this value.

- STEPGEN_MAXACCEL

- = 21.0 (hal) Acceleration limit for the step generator. This should be 1% to 10% larger than the axis MAX_ACCELERATION. This value improves the tuning of stepgen’s "position loop". If you have added backlash compensation to an axis then this should be 1.5 to 2 times greater than MAX_ACCELERATION.

- STEPGEN_MAXVEL

- =* *1.4 (hal) Older configuration files have a velocity limit for the step generator as well. If specified, it should also be 1% to 10% larger than the axis MAX_VELOCITY. Subsequent testing has shown that use of STEPGEN_MAXVEL does not improve the tuning of stepgen’s position loop.

- CYCLE_TIME

- =* *0.100 The period, in seconds, at which EMCIO will run. Making it 0.0 or a negative number will tell EMCIO not to sleep at all. There is usually no need to change this number.

- TOOL_TABLE

- =* *tool.tbl The file which contains tool information, described in the User Manual.

- TOOL_CHANGE_POSITION

- = 0 0 2 Specifies the X Y Z location to move to when performing a tool change if three digits are used. Specifies the X Y Z A B C location when 6 digits are used. Specifies the X Y Z A B C U V W location when 9 digits are used. Tool Changes can be combined. For example if you combine the quill up with change position you can move the Z first then the X and Y.

- TOOL_CHANGE_WITH_SPINDLE_ON = 1

The spindle will be left on during the tool change when the value is

- Useful for lathes or machines where the material is in the spindle not the tool.

- TOOL_CHANGE_QUILL_UP = 1

- The Z axis will be moved to machine zero prior to the tool change when the value is 1. This is the same as issuing a G0 G53 Z0.

- TOOL_CHANGE_AT_G30 = 1

- The machine is moved to reference point defined by parameters 5181-5186 for G30 if the value is 1. For more information on G30 and Parameters see the G Code Manual.

- RANDOM_TOOLCHANGER = 1

- This is for machines that cannot place the tool back into the pocket it came from. For example, machines that exchange the tool in the active pocket with the tool in the spindle.

Homing seems simple enough - just move each joint to a known location, and set EMC’s internal variables accordingly. However, different machines have different requirements, and homing is actually quite complicated.

There are four possible homing sequences, along with the associated configuration parameters as shown in the following table. For a more detailed description of what each configuration parameter does, see the following section.

| SEARCH_VEL | LATCH_VEL | USE_INDEX | Homing Type |

|---|---|---|---|

nonzero | nonzero | NO | Switch-only |

nonzero | nonzero | YES | Switch + Index |

0 | nonzero | YES | Index-only |

0 | 0 | NO | None |

Other combinations | Error |

There are six pieces of information that determine exactly how the home sequence behaves. They are defined in an [AXIS] section of the inifile.

The default value is zero. A value of zero causes EMC to assume that there is no home switch; the search stage of homing is skipped.

If HOME_SEARCH_VEL is non-zero, then EMC assumes that there is a home switch. It begins by checking whether the home switch is already tripped. If tripped it backs off the switch at HOME_SEARCH_VEL. The direction of the back-off is opposite the sign of HOME_SEARCH_VEL. Then it searches for the home switch by moving in the direction specified by the sign of HOME_SEARCH_VEL, at a speed determined by its absolute value. When the home switch is detected, the joint will stop as fast as possible, but there will always be some overshoot. The amount of overshoot depends on the speed. If it is too high, the joint might overshoot enough to hit a limit switch or crash into the end of travel. On the other hand, if HOME_SEARCH_VEL is too low, homing can take a long time.

Specifies the speed and direction that EMC uses when it makes its final accurate determination of the home switch (if present) and index pulse location (if present). It will usually be slower than the search velocity to maximise accuracy. If HOME_SEARCH_VEL and HOME_LATCH_VEL have the same sign, then the latch phase is done while moving in the same direction as the search phase. (In that case, EMC first backs off the switch, before moving towards it again at the latch velocity.) If HOME_SEARCH_VEL and HOME_LATCH_VEL have opposite signs, the latch phase is done while moving in the opposite direction from the search phase. That means EMC will latch the first pulse after it moves off the switch. If HOME_SEARCH_VEL is zero (meaning there is no home switch), and this parameter is nonzero, EMC goes ahead to the index pulse search. If HOME_SEARCH_VEL is non-zero and this parameter is zero, it is an error and the homing operation will fail. The default value is zero.

It specifies the speed that EMC uses when it makes its move from HOME_OFFSET to the HOME position. If the HOME_FINAL_VEL is missing from the ini file, then the maximum joint speed is used to make this move. The value must a positive number.

Can hold the values YES / NO. This flag determines whether EMC will ignore the limit switch inputs. Some machine configurations do not use a separate home switch, instead they route one of the limit switch signals to the home switch input as well. In this case, EMC needs to ignore that limit during homing. The default value for this parameter is NO.

Specifies whether or not there is an index pulse. If the flag is true (HOME_USE_INDEX = YES), EMC will latch on the rising edge of the index pulse. If false, EMC will latch on either the rising or falling edge of the home switch (depending on the signs of HOME_SEARCH_VEL and HOME_LATCH_VEL). The default value is NO.

Contains the location of the home switch or index pulse, in joint coordinates. It can also be treated as the distance between the point where the switch or index pulse is latched and the zero point of the joint. After detecting the index pulse, EMC sets the joint coordinate of the current point to HOME_OFFSET. The default value is zero.

The position that the joint will go to upon completion of the homing sequence. After detecting the index pulse, and setting the coordinate of that point to HOME_OFFSET, EMC makes a move to HOME as the final step of the homing process. The default value is zero. Note that even if this parameter is the same as HOME_OFFSET, the axis will slightly overshoot the latched position as it stops. Therefore there will always be a small move at this time (unless HOME_SEARCH_VEL is zero, and the entire search/latch stage was skipped). This final move will be made at the joint’s maximum velocity. Since the axis is now homed, there should be no risk of crashing the machine, and a rapid move is the quickest way to finish the homing sequence. [3]

If there is not a separate home switch input for this axis, but a number of momentary switches wired to the same pin, set this value to 1 to prevent homing from starting if one of the shared switches is already closed. Set this value to 0 to permit homing even if the switch is already closed.

Used to define a multi-axis homing sequence HOME ALL and enforce homing order (e.g., Z may not be homed if X is not yet homed). An axis may be homed after all axes with a lower HOME_SEQUENCE have already been homed and are at the HOME_OFFSET. If two axes have the same HOME_SEQUENCE, they may be homed at the same time. If HOME_SEQUENCE is -1 or not specified then this joint will not be homed by the HOME ALL sequence. HOME_SEQUENCE numbers start with 0 and there may be no unused numbers.

See also the manual pages motion(9) and iocontrol(1).

Motion is loaded with the motmod command. A kins should be loaded before motion.

loadrt motmod [base_period_nsec=period] [servo_period_nsec=period] [traj_period_nsec=period] [num_joints=[0-9] ([num_dio=1-64] num_aio=1-16])]

If the number of digital I/O needed is above the default of 4 you can add up to 64 digital I/O by using the num_dio option when loading motmod.

If the number of analog I/O needed is more that the default of 4 you can add up to 16 analog I/O by using the num_aio option when loading motmod.

These pins, parameters, and functions are created by the realtime

motmod module.

- motion.adaptive-feed

-

(float, in) When adaptive feed is enabled with

M52 P1, the commanded velocity is multiplied by this value. This effect is multiplicative with the NML-level feed override value and motion.feed-hold. - motion.analog-in-00

- (float, in) These pins (00, 01, 02, 03 or more if configured) are controlled by M66.

- motion.analog-out-00

- (float, out) These pins (00, 01, 02, 03 or more if configured) are controlled by M67 or M68.

- motion.coord-error

- (bit, out) TRUE when motion has encountered an error, such as exceeding a soft limit

- motion.coord-mode

- (bit, out) TRUE when motion is in "coordinated mode", as opposed to "teleop mode"

- motion.current-vel

- (float, out) The current tool velocity in user units per second.

- motion.digital-in-00

- (bit, in) These pins (00, 01, 02, 03 or more if configured) are controlled by M62-65.

- motion.digital-out-00

-

(bit, out) These pins (00, 01, 02, 03 or more if configured) are

controlled by the

M62-65. - motion.distance-to-go

- (float,out) The distance remaining in the current move.

- motion.enable

- (bit, in) If this bit is driven FALSE, motion stops, the machine is placed in the "machine off" state, and a message is displayed for the operator. For normal motion, drive this bit TRUE.

- motion.feed-hold

-

(bit, in) When Feed Stop Control is enabled with

M53 P1, and this bit is TRUE, the feed rate is set to 0. - motion.in-position

- (bit, out) TRUE if the machine is in position.

- motion.motion-enabled

- (bit, out) TRUE when in "machine on" state.

- motion.on-soft-limit

- (bit, out) TRUE when the machine is on a soft limit.

- motion.probe-input

-

(bit, in)

G38.xuses the value on this pin to determine when the probe has made contact. TRUE for probe contact closed (touching), FALSE for probe contact open. - motion.program-line

- (s32, out) The current program line while executing. Zero if not running or between lines while single stepping.

- motion.requested-vel

- (float, out) The current requested velocity in user units per second from the F=n setting in the G Code file. No feed overrides or any other adjustments are applied to this pin.

- motion.spindle-at-speed

-

(bit, in) Motion will pause until this pin is TRUE, under the

following conditions: before the first feed move after each spindle

start or speed change; before the start of every chain of

spindle-synchronized moves; and if in CSS mode, at every rapid to feed

transition. This input can be used to ensure that the spindle is up to

speed before starting a cut, or that a lathe spindle in CSS mode has

slowed down after a large to small facing pass before starting the next

pass at the large diameter. Many VFDs have an "at speed" output.

Otherwise, it is easy to generate this signal with the

HAL nearcomponent, by comparing requested and actual spindle speeds. - motion.spindle-brake

- (bit, out) TRUE when the spindle brake should be applied.

- motion.spindle-forward

- (bit, out) TRUE when the spindle should rotate forward.

- motion.spindle-index-enable

- (bit, I/O) For correct operation of spindle synchronized moves, this pin must be hooked to the index-enable pin of the spindle encoder.

- motion.spindle-on

- (bit, out) TRUE when spindle should rotate.

- motion.spindle-reverse

- (bit, out) TRUE when the spindle should rotate backward

- motion.spindle-revs

-

(float, in) For correct operation of spindle synchronized moves, this

signal must be hooked to the position pin of the spindle encoder. The

spindle encoder position should be scaled such that spindle-revs

increases by 1.0 for each rotation of the spindle in the clockwise

(

M3) direction. - motion.spindle-speed-in

-

(float, in) Feedback of actual spindle speed in rotations per second.

This is used by feed-per-revolution motion (

G95). If your spindle encoder driver does not have a velocity output, you can generate a suitable one by sending the spindle position through addtcomponent. - motion.spindle-speed-out

-

(float, out) Commanded spindle speed in rotations per minute. Positive

for spindle forward (

M3), negative for spindle reverse (M4). - motion.spindle-speed-out-rps

-

(float, out) Commanded spindle speed in rotations per second. Positive

for spindle forward (

M3), negative for spindle reverse (M4). - motion.teleop-mode

- (bit, out) TRUE when motion is in "teleop mode", as opposed to "coordinated mode"

- motion.tooloffset.w

-

(float, out) shows the w offset in effect; it could come from the tool

table (

G43active), or it could come from the gcode (G43.1active) - motion.tooloffset.x

-

(float, out) shows the x offset in effect; it could come from the tool

table (

G43active), or it could come from the gcode (G43.1active) - motion.tooloffset.z

-

(float, out) shows the z offset in effect; it could come from the tool

table (

G43active), or it could come from the gcode (G43.1active)

Many of these parameters serve as debugging aids, and are subject to change or removal at any time.

- motion-command-handler.time

- (s32, RO)

- motion-command-handler.tmax

- (s32, RW)

- motion-controller.time

- (s32, RO)

- motion-controller.tmax

- (s32, RW)

- motion.debug-bit-0

- (bit, RO) This is used for debugging purposes.

- motion.debug-bit-1

- (bit, RO) This is used for debugging purposes.

- motion.debug-float-0

- (float, RO) This is used for debugging purposes.

- motion.debug-float-1

- (float, RO) This is used for debugging purposes.

- motion.debug-float-2

- (float, RO) This is used for debugging purposes.

- motion.debug-float-3

- (float, RO) This is used for debugging purposes.

- motion.debug-s32-0

- (s32, RO) This is used for debugging purposes.

- motion.debug-s32-1

- (s32, RO) This is used for debugging purposes.

- motion.servo.last-period

- (u32, RO) The number of CPU cycles between invocations of the servo thread. Typically, this number divided by the CPU speed gives the time in seconds, and can be used to determine whether the realtime motion controller is meeting its timing constraints

- motion.servo.last-period-ns

- (float, RO)

- motion.servo.overruns

- (u32, RW) By noting large differences between successive values of motion.servo.last-period , the motion controller can determine that there has probably been a failure to meet its timing constraints. Each time such a failure is detected, this value is incremented.

These pins and parameters are created by the realtime motmod

module. These are actually joint values, but the pins and parameters

are still called "axis.N".[4] They are read and updated by the motion-controller function.

- axis.N.active

- (bit, out)

- axis.N.amp-enable-out

- (bit, out) TRUE if the amplifier for this joint should be enabled

- axis.N.amp-fault-in

- (bit, in) Should be driven TRUE if an external fault is detected with the amplifier for this joint

- axis.N.backlash-corr

- (float, out)

- axis.N.backlash-filt

- (float, out)

- axis.N.backlash-vel

- (float, out)

- axis.N.coarse-pos-cmd

- (float, out)

- axis.N.error

- (bit, out)

- axis.N.f-error

- (float, out)

- axis.N.f-error-lim

- (float, out)

- axis.N.f-errored

- (bit, out)

- axis.N.faulted

- (bit, out)

- axis.N.free-pos-cmd

- (float, out)

- axis.N.free-tp-enable

- (bit, out)

- axis.N.free-vel-lim

- (float, out)

- axis.N.home-sw-in

- (bit, in) Should be driven TRUE if the home switch for this joint is closed.

- axis.N.homed

- (bit, out)

- axis.N.homing

- (bit, out) TRUE if the joint is currently homing

- axis.N.in-position

- (bit, out)

- axis.N.index-enable

- (bit, I/O)

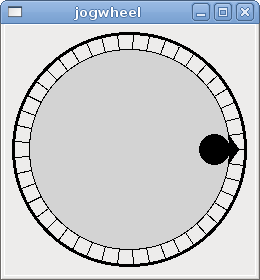

- axis.N.jog-counts

- (s32, in) Connect to the "counts" pin of an external encoder to use a physical jog wheel.

- axis.N.jog-enable

- (bit, in) When TRUE (and in manual mode), any change in "jog-counts" will result in motion. When false, "jog-counts" is ignored.

- axis.N.jog-scale

- (float, in) Sets the distance moved for each count on "jog-counts", in machine units.

- axis.N.jog-vel-mode

- (bit, in) When FALSE (the default), the jogwheel operates in position mode. The axis will move exactly jog-scale units for each count, regardless of how long that might take. When TRUE, the wheel operates in velocity mode - motion stops when the wheel stops, even if that means the commanded motion is not completed.

- axis.N.joint-pos-cmd

- (float, out) The joint (as opposed to motor) commanded position. There may be an offset between the joint and motor positions—for example, the homing process sets this offset.

- axis.N.joint-pos-fb

- (float, out) The joint (as opposed to motor) feedback position.

- axis.N.joint-vel-cmd

- (float, out)

- axis.N.kb-jog-active

- (bit, out)

- axis.N.motor-pos-cmd

- (float, out) The commanded position for this joint.

- axis.N.motor-pos-fb

- (float, in) The actual position for this joint.

- axis.N.neg-hard-limit

- (bit, out)

- axis.N.pos-lim-sw-in

- (bit, in) Should be driven TRUE if the positive limit switch for this joint is closed

- axis.N.pos-hard-limit

- (bit, out)

- axis.N.neg-lim-sw-in

- (bit, in) Should be driven TRUE if the negative limit switch for this joint is closed

- axis.N.wheel-jog-active

- (bit, out)

These pins are created by the userspace IO controller, usually called

io.

- iocontrol.0.coolant-flood

- (bit, out) TRUE when flood coolant is requested

- iocontrol.0.coolant-mist

- (bit, out) TRUE when mist coolant is requested

- iocontrol.0.emc-enable-in

- (bit, in) Should be driven FALSE when an external E-Stop condition exists

- iocontrol.0.lube

- (bit, out) TRUE when lube is commanded

- iocontrol.0.lube_level

- (bit, in) Should be driven TRUE when lube level is high enough

- iocontrol.0.tool-change

- (bit, out) TRUE when a tool change is requested

- iocontrol.0.tool-changed

- (bit, in) Should be driven TRUE when a tool change is completed

- iocontrol.0.tool-number

- (s32, out) The current tool number

- iocontrol.0.tool-prep-number

- (s32, out) The number of the next tool, from the RS274NGC T-word

- iocontrol.0.tool-prepare

- (bit, out) TRUE when a tool prepare is requested

- iocontrol.0.tool-prepared

- (bit, in) Should be driven TRUE when a tool prepare is completed

- iocontrol.0.user-enable-out

- (bit, out) FALSE when an internal E-Stop condition exists

- iocontrol.0.user-request-enable

- (bit, out) TRUE when the user has requested that E-Stop be cleared

GladeVCP is an EMC2 component which adds the ability to add a virtual control panel to EMC user interfaces like Axis or Touchy. It is similar to PyVCP; whereas PyVCP panels are created by editing an XML file manually, GladeVCP uses the glade WYSIWYG user interface editor. Therefore, it’s faster and easier to create visually pleasing panels with GladeVCP.

- Note

- Until GladeVCP is fully integrated with EMC2 please refer to the EMC wiki page GladeVcpSetup for instructions on installing and setting up GladeVCP.

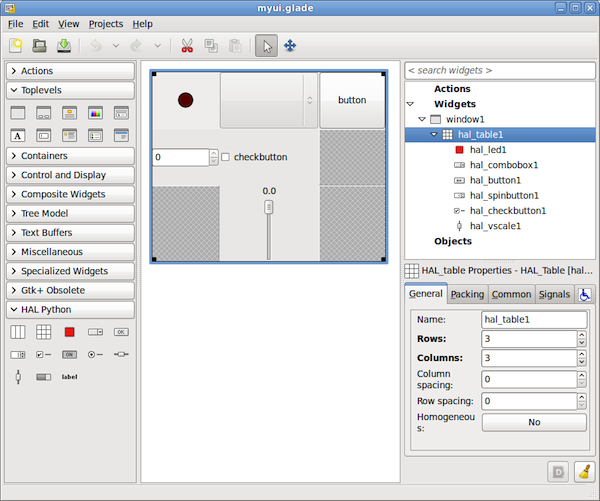

Either modify an existing UI component, or start a new one with running glade. In the left tab, expand the HAL Python components. Create a window as top level window from the Toplevels section, which by default will be named window1. Leave that name as is - gladevcp assumes the top level window has this name. Add a HAL_Box or a HAL_Table from HAL Python to the frame, and pick and place some elements like LED, button etc in its box.

This will look like so:

Select File→Save as, give it a name like myui.ui and make sure it’s saved as GtkBuilder file (radio button left bottom corner in Save dialog). The convention for GtkBuilder file extension is .ui. You can now run it with:

gladevcp myui.ui

While you could run your UI as a separate top level window side-by-side with Axis, having it within the Axis frame as a tab side-by-side with the Preview and DRO tabs is more elegant. To do so, edit your .ini file and add two variables to the DISPLAY section of ini file:

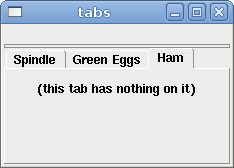

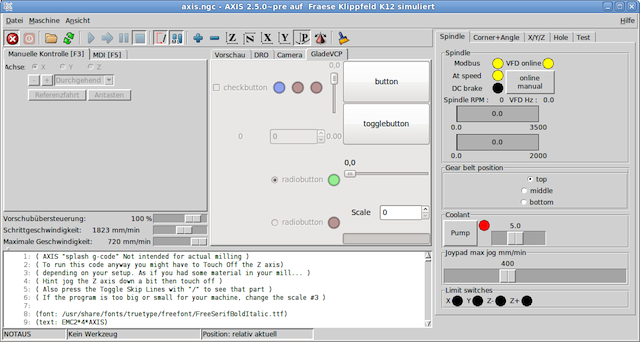

Try it out by running Axis - there should be a new tab called GladeVCP near the DRO tab. Select that tab, you should see the example panel nicely fit within Axis like so:

Touchy also understands EMBED_TAB_NAME/EMBED_TAB_COMMAND variables from INI file so instructions for it are equal to Axis.

To be useful, the pins in your UI need to be linked to the rest of your setup. Usually this is done by running one or several HAL files through the HALFILE and POSTGUI_HALFILE statements in the HAL section of your .ini file.

For gladevcp components this not currently possible because all of these HALFILE statements are run before gladevcp is started, so linking to your UI’s pins from there would refer to pins which do not yet exist. You therefore need to prepare a file of all HAL commands which refer to / link with your UI’s pins and pass it to the gladevcp command in the EMBED_TAB_COMMAND statement like so:

EMBED_TAB_COMMAND = gladevcp -c gladevcp-test -H gladevcp-test.hal -w

There is an example gladevcp-test.hal file in the emc2-dev/lib/python/gladevcp directory. Before using it in the EMBED_TAB_NAME statement, make sure the loadusr statements at the top are commented out.

This is just a very minimal example to convey the idea - for a detailed description on how to program a gladevcp application, see GladeVCPprogramming and HalWidgets.

gladevcp cannot only manipulate or display HAL pins, you can also write regular event handlers in Python. This could be used, among others, to execute MDI commands. Here’s how you do it:

Write a Python module like so and save as e.g. handlers.py:

nhits = 0

def on_button_press(gtkobj,data=None):

global nhits nhits += 1 gtkobj.set_label("hits: %d" % nhits)In glade, define a button or HAL button, select the Signals tab, and in the GtkButton properties select the pressed line. Enter on_button_press there, and save the glade file.

Then add the option -u handlers.py to the gladevcp command line. If your event handlers are spread over several files, just add multiple -u <pyfilename> options.

Now, pressing the button should change its label since it’s set in the callback function.

What the -u flag does is: all Python functions in this file are collected and setup as potential callback handlers for your Gtk widgets - they can be referenced from glade Signals tabs. The callback handlers are called with the particular object instance as parameter, like the GtkButton instance above, so you can apply any GtkButton method from there.

Or do some more useful stuff, like calling an MDI command!

See also man gladevcp . This is the usage message when you run gladevcp -h:

Usage: gladevcp [options] myfile.ui

Options:

- -h, --help

- show this help message and exit

- -c NAME

- Set component name to NAME. Default is base name of UI file

- -d

- Enable debug output

- -g GEOMETRY

- Set geometry WIDTHxHEIGHT+XOFFSET+YOFFSET.Values are in pixel units, XOFFSET/YOFFSET is referenced from top left of screen use -g WIDTHxHEIGHT for just setting size or -g +XOFFSET+YOFFSET for just position -H FILE execute hal statements from FILE with halcmd after the component is set up and ready

- -x XID

- Re-parent gladevcp into an existing window XID instead of creating a new top level window

- -u FILE

- Use File’s as additional user defined modules with handlers

- -U USEROPT

- pass USEROPTs to Python modules

- make sure your have the development version of emc2 installed. You don’t need the axisrc file any more, this was mentioned in the old GladeVcp wiki page.

- run gladevcp or Axis from a terminal window. If you get Python errors, check whether there’s still a /usr/lib/python2.6/dist-packages/hal.so file lying around besides the newer /usr/lib/python2.6/dist-packages/_hal.so (note underscore); if yes, remove the hal.so file. It has been superseded by hal.py in the same directory and thus creates confusion.

- if you’re using run-in-place, do a make clean to remove any accidentially left over hal.so file, then make.

- if you’re using HAL_table or HAL_HBox widgets, be aware they have an HAL pin associated with it which is off by default. This pin controls whether these container’s children are active or not.

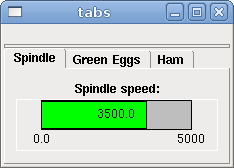

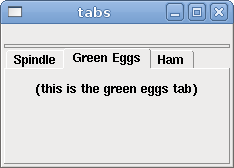

- 6.1. PyVCP to GladeVCP

- 6.2. Hal Widgets

- 6.2.1. Widget and HAL pin naming

- 6.2.2. Setting pin and widget values

- 6.2.3. The hal-pin-changed signal

- 6.2.4. Buttons

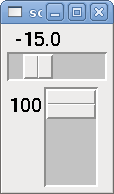

- 6.2.5. Scales

- 6.2.6. SpinButton

- 6.2.7. Label

- 6.2.8. Containers: HAL_HBox and HAL_Table

- 6.2.9. LED

- 6.2.10. ProgressBar

- 6.2.11. ComboBox

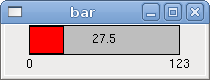

- 6.2.12. Bars

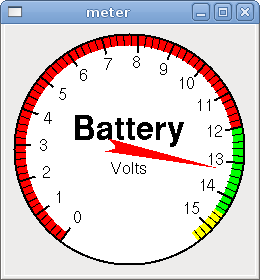

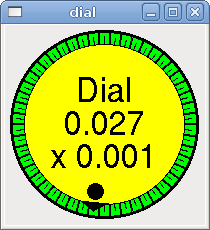

- 6.2.13. Meter

- 6.2.14. Gremlin tool path preview for .ngc files

- 6.3. Action Widgets

- 6.4. User Defined Actions

- 6.4.1. HAL value change events

- 6.4.2. Persistent values in GladeVCP

- 6.4.3. Programming model

- 6.4.4. Initialization sequence

- 6.4.5. Multiple callbacks with the same name

- 6.4.6. The gladevcp -U <useropts> flag

- 6.4.7. Persistence

- 6.4.8. Hand-editing .ini files

- 6.4.9. Adding HAL pins

- 6.4.10. Adding timers

- 6.4.11. Implementation note: Key handling in Axis

- 6.4.12. FAQ

- 6.4.13. Examples, and rolling your own gladevcp application

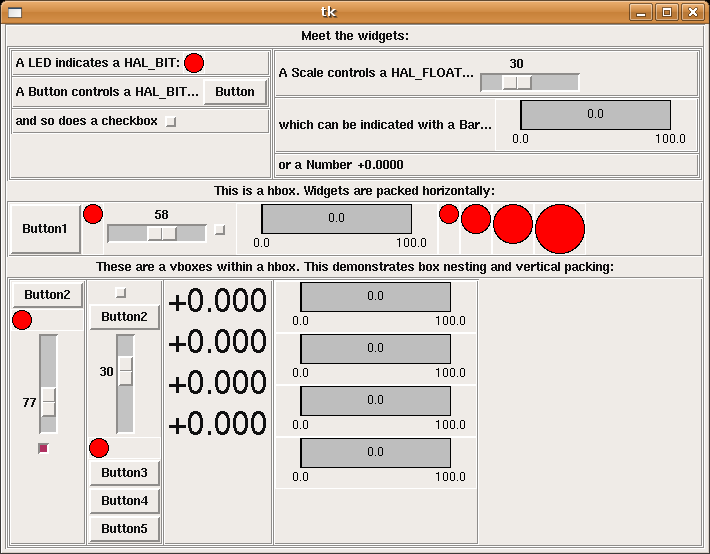

Stock gladevcp can be used pretty much in the style of PyVCP - the major difference being that in the case of gladevcp, the glade user interface editor is used to design a screen layout, whereas PyVCP is driven by manually edited XML files. Also, PyVCP uses the TkInter widgets, whereas gladevcp uses the much richer GTK toolkit. Both support HAL widgets - widgets with one or more associated HAL pin which is the interface to the rest of EMC. Stock gladevcp and PyVCP panels are really just a bunch of virtual switches, dials, leds an so forth, wired to the outside world through the HAL layer, designed to set and read ints, bits and floats values.

Most widget sets, and their associated user interface editors, support the concept of callbacks - functions in user-written code which are executed when something happens in the UI - events like mouse clicks, characters typed, mouse movement, timer events, window hiding and exposure and so forth. Both PyVCP and stock gladevcp mainly do two things: mapping events on HAL widgets to actions like a value change of the associated HAL pin, and in the other direction - detecting if HAL pin values changed and updating the associated widget, like a LED, a meter, a bar, or just some label displaying a value. However, neither PyVCP nor stock gladevcp provide support for other actions than changing HAL values. Doing something more complex, like executing MDI commands to call a G-code subroutine, is outside scope.

GladeVcp includes a collection of Gtk widgets with attached HAL pins called HAL Widgets, intended to control, display or otherwise interact with the EMC HAL layer. They are intended to be used with the glade user interface editor. With proper installation, the HAL Widgets should show up in glade’s HAL Python widget group. Many HAL specific fields in the glade General section have an associated mouse-over tool tip.

HAL signals come in two variants, bits and numbers. Bits are off/on signals. Numbers can be "float", "s32" or "u32". For more information on HAL data types see the [→] section. The GladeVcp widgets can either display the value of the signal with an indicator widget, or modify the signal value with a control widget. Thus there are four classes of GladeVcp widgets that you can connect to a HAL signal. Another class of helper widgets allow you to organize and label your panel.

- Widgets for indicating "bit" signals: HAL_LED

- Widgets for controlling "bit" signals: HAL_Button, HAL_RadioButton, HAL_CheckButton, HAL_RadioButton

- Widgets for indicating "number" signals: HAL_Label, HAL_ProgressBar, HAL_Bar, HAL_VBar, HAL_Meter

- Widgets for controlling "number" signals: HAL_SpinButton, HAL_HScale, HAL_VScale

- Helper widgets: HAL_Table, HAL_HBox

- Tool Path preview: HAL_Gremlin

HAL Widgets inherit methods, properties and signals from the underlying Gtk widgets, so it is helpful to consult the Gtk and PyGTK documentation as well.

Most HAL widgets have a single associated HAL pin with the same name as the widget (glade: General→Name). Exceptions to this rule currently are the HAL_Spinbutton, which has two pins: a <widgetname>-f (float) and a <widgetname>-s (s32) pin, and the HAL_ProgressBar, which has a <widgetname> value input pin, and a <widgetname>.scale input pin.

As a general rule, if you need to set a HAL output widget’s value from Python code, do so by calling the underlying Gtk setter (e.g. set_active(), set_value()) - do not try to set the associated pin’s value by halcomp[pinname] = value directly because the widget will not notice.

It might be tempting to set HAL widget input pins programmatically. Note this defeats the purpose of an input pin in the first place - it should be linked to, and react to signals generated by other HAL components. While there is currently no write protection on writing to input pins in HAL Python, this doesn’t make sense. You might use setp pinname value in the associated halfile for testing though.

It is perfectly OK to set an output HAL pin’s value with halcomp[pinname] = value provided this HAL pin is not associated with a widget, that is, has been created by the hal_glib.GPin(halcomp.newpin(<name>,<type>,<direction>) method (see GladeVCProgramming for an example).

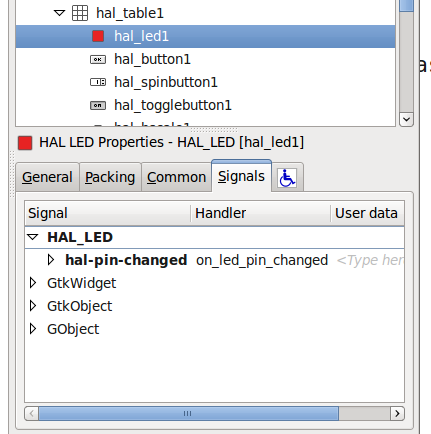

Event-driven programming means that the UI tells you when "something happens" - through a callback, like when a button was pressed. The output HAL widgets (those which display a HAL pin’s value) like LED, Bar, VBar, Meter etc, support the hal-pin-changed signal which may cause a callback into your Python code when - well, a HAL pin changes its value. This means there’s no more need for permanent polling of HAL pin changes in your code, the widgets do that in the background and let you know. The example in configs/gladevcp/examples/complex shows how this is handled in Python.

Here is an example how to set a hal-pin-changed signal for a HAL_LED in the glade UI editor:

This group of widget is derived from various Gtk buttons and consists of HAL_Button, HAL_ToggleButton, HAL_RadioButton and CheckButton widgets. All of them have a single output BIT pin named identical to the widget. Buttons have no additional properties compared to their base Gtk classes.

- HAL_Button: instantaneous action, does not retain state. Important signal: pressed

- HAL_ToggleButton, HAL_CheckButton: retains on/off state. Important signal: toggled

- HAL_RadioButton: a one-of-many group. Important signal: toggled (per button).

- Important common methods: set_active(), get_active()

- Important properties: label, image

Hint: Defining radio button groups in glade:

- decide on default active button

- in the other button’s General→Group select the default active button’s name in the Choose a Radio Button in this project dialog.

See configs/gladevcp/by-widget/radiobutton for a gladevcp application and UI file for working with radio buttons.

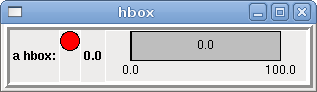

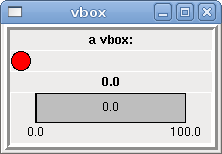

HAL_HScale and HAL_VScale are derived from the GtkHScale and GtkVScale respectively. They have one output FLOAT pin with name equal to widget name. Scales have no additional properties.

Hint: To make a scale useful in glade, add an Adjustment (General→Adjustment→New or existing adjustment) and edit the adjustment object. It defines the default/min/max/increment

values. Also, set adjustment Page size and Page increment to zero to avoid warnings.

HAL SpinButton is derived from GtkSpinButton and holds two pins:

Hint: to be useful, Spinbuttons need an adjustment value like scales, see above.

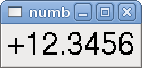

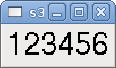

HAL_Label is simple widget based on GtkLabel which represents a HAL pin value in a user-defined format. The pin’s HAL type depends on the label_pin_type property (0:S32, 1:float, 2:U32), see also the tooltip on General→HAL pin type (note this is different from PyVCP which has three label widgets, one for each type).

The text displayed depends on the text_template property - an Python format string to represent the pin value. It defaults to "%s" (values are converted by the str() function) but may contain anything legit in a as argument to Pythons format() method.

Example: Distance: %.03f will display the text and the pin value with 3 fractional digits padded with zeros for a FLOAT pin.

Compared to their Gtk counterparts they have one input BIT pin which controls if their child widgets are sensitive or not. If the pin is low then child widgets are inactive which is the default.

Hint: if you find some part of your gladevcp application is grayed out (insensitive), see whether a container’s pin is unset.

The HAL_Led simulates a real indicator LED . It has a single input BIT pin which controls it’s state: ON or OFF. Leds have several properties which control their look and feel:

- on_color: a String defining ON color of led. May be any valid gtk.gdk.Color name. Not working on Ubuntu 8.04.

- off_color: String defining OFF color of led. May be any valid gtk.gdk.Color name or special value "dark". "dark" means that OFF color will be set to 0.4 value of ON color. Not working on Ubuntu 8.04.

- pick_color_on, pick_color_off: Colors for ON and OFF states may be represented as #RRRRGGGGBBBB strings. These are optional properties which have precedence over "on_color" and "off_color".

- led_size: LED radius (for square - half of LED’s side)

- led_shape: LED Shape. Valid values are 0 for round, 1 for oval and 2 for square shapes.

- led_blink_rate: if set and led is ON then it’s blinking. Blink frequency is equal to "led_blink_rate" specified in milliseconds.

As an input widget, LED also supports the hal-pin-changed signal. If you want to get a notification in your code when the LED’s HAL pin was changed, then connect this signal to a handler, for example on_led_pin_changed and provide the handler as follows:

def on_led_pin_changed(self,hal_led,data=None): print "on_led_pin_changed() - HAL pin value:",hal_led.hal_pin.get()

This will be called at any edge of the signal and also during program start up to report the current value.